In today’s increasingly competitive global market, product quality and stability have become key factors for companies aiming to secure overseas markets. However, many enterprises are encountering frequent issues with Voltage tripping and Sterilizer corrosion during export processes. These problems not only affect the normal functioning of the products but also severely hinder export growth. This article explores the causes and solutions for these challenges from six key perspectives to help companies boost their product competitiveness and achieve stable export performance.

Market Conditions and Export Pressures

Firstly, as international demand for high-quality electrical equipment and medical devices continues to grow, exported products must exhibit stable electrical performance and durable material properties. In practice, frequent Voltage tripping issues lead to unexpected power interruptions in overseas markets, while Sterilizer corrosion during transportation or prolonged use adversely affects both the product’s appearance and functionality. As a result, companies are under unprecedented pressure to meet international quality standards.

Analyzing the Root Causes of Voltage Tripping

Secondly, Voltage tripping issues often arise from factors such as inadequate circuit design, improper component selection, or insufficient control over manufacturing processes. For instance, if critical components within the power management system cannot withstand voltage fluctuations or overload, the built-in protection mechanisms may trigger frequently, resulting in recurring voltage tripping. A thorough analysis of the design and production processes is essential to identify and resolve these issues.

Investigating the Causes of Sterilizer Corrosion

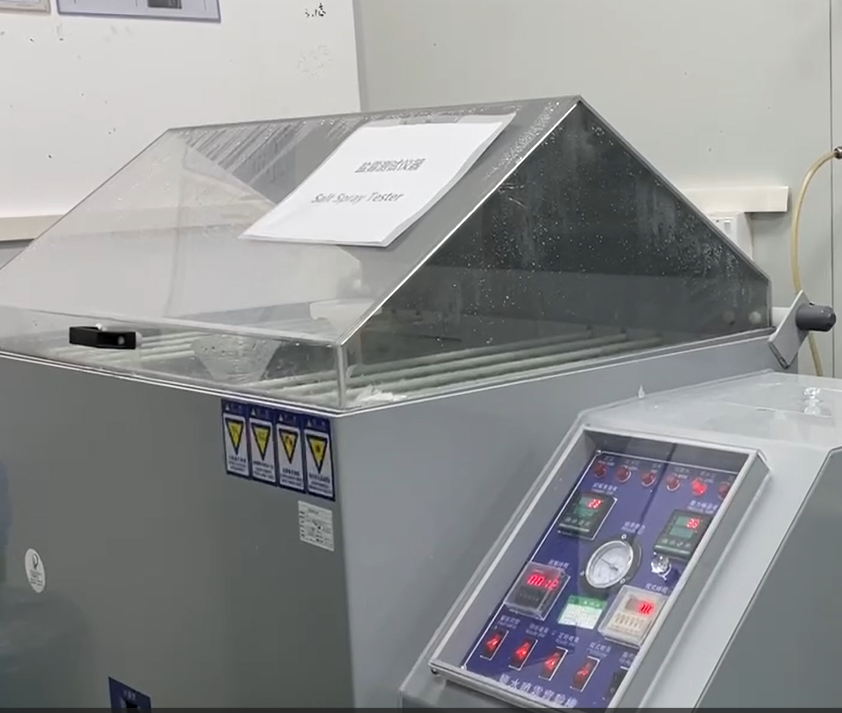

Thirdly, Sterilizer corrosion is largely associated with material selection, surface treatment, and environmental adaptability. Typically, materials with a short lifespan or poor corrosion resistance are prone to corrosion under conditions of high temperature, humidity, or frequent exposure to chemical agents, thereby compromising both the sterilizing efficiency and the lifespan of the equipment. To address this, companies need to re-evaluate material performance and implement stricter protective measures in the manufacturing process.

Technological Upgrades and Process Improvements

To effectively tackle both Voltage tripping and Sterilizer corrosion, companies must continuously innovate in technology and process. Firstly, optimizing circuit design, selecting higher-spec components, and improving power management strategies can mitigate the impact of voltage fluctuations. Secondly, addressing sterilizer corrosion through the use of corrosion-resistant alloys or advanced surface coating techniques can not only extend the equipment’s service life but also ensure sustained sterilization performance. Technological upgrades and process improvements together can significantly enhance product competitiveness in international markets.

Comprehensive Quality Control and Pre-shipment Testing

Furthermore, establishing a rigorous quality management system and thorough pre-shipment testing is critical in preventing issues related to Voltage tripping and Sterilizer corrosion. By integrating intelligent monitoring systems and automated testing equipment, companies can monitor electrical performance and material durability in real time throughout the production process. Additionally, using big data analysis to adjust production parameters promptly can ensure that every product meets international standards, thereby reducing the risk of returns and claims due to quality issues.

Future Outlook and Continuous Improvement Strategies

Lastly, looking ahead, the ongoing development of smart manufacturing and new material technologies promises further breakthroughs in voltage management and anti-corrosion techniques. Companies should continue to invest in research and development, keep a close eye on industry trends and evolving international standards, and drive innovation in electrical systems and material applications. Strengthening cooperation with research institutions and industry associations will also help explore advanced technical applications, building a robust technological barrier for exports. Continuous optimization of product quality and technology is essential for gaining higher recognition and trust in the global market.

In conclusion, Voltage tripping and Sterilizer corrosion are emerging as significant obstacles to exports. By thoroughly analyzing the root causes, implementing technological upgrades, optimizing manufacturing processes, and establishing stringent quality management systems, companies can not only reduce product failure rates but also significantly enhance their competitiveness in the international market. Continuous improvement and innovation will pave the way for broader development opportunities in an increasingly globalized competition.

https://www.powsmart.com/about-powsmart/