In the current context of rising global environmental awareness, energy saving and emission reduction has become a top priority for manufacturing companies. As an electric toothbrush factory with 20 years of OEM/ODM experience, Powsmart is not only committed to the production of high-quality products, but also actively implements energy-saving and emission reduction measures during the production process to achieve the goal of sustainable development. In this paper, we will discuss the energy saving and emission reduction measures adopted by Powsmart in the production of electric toothbrushes and their effectiveness.

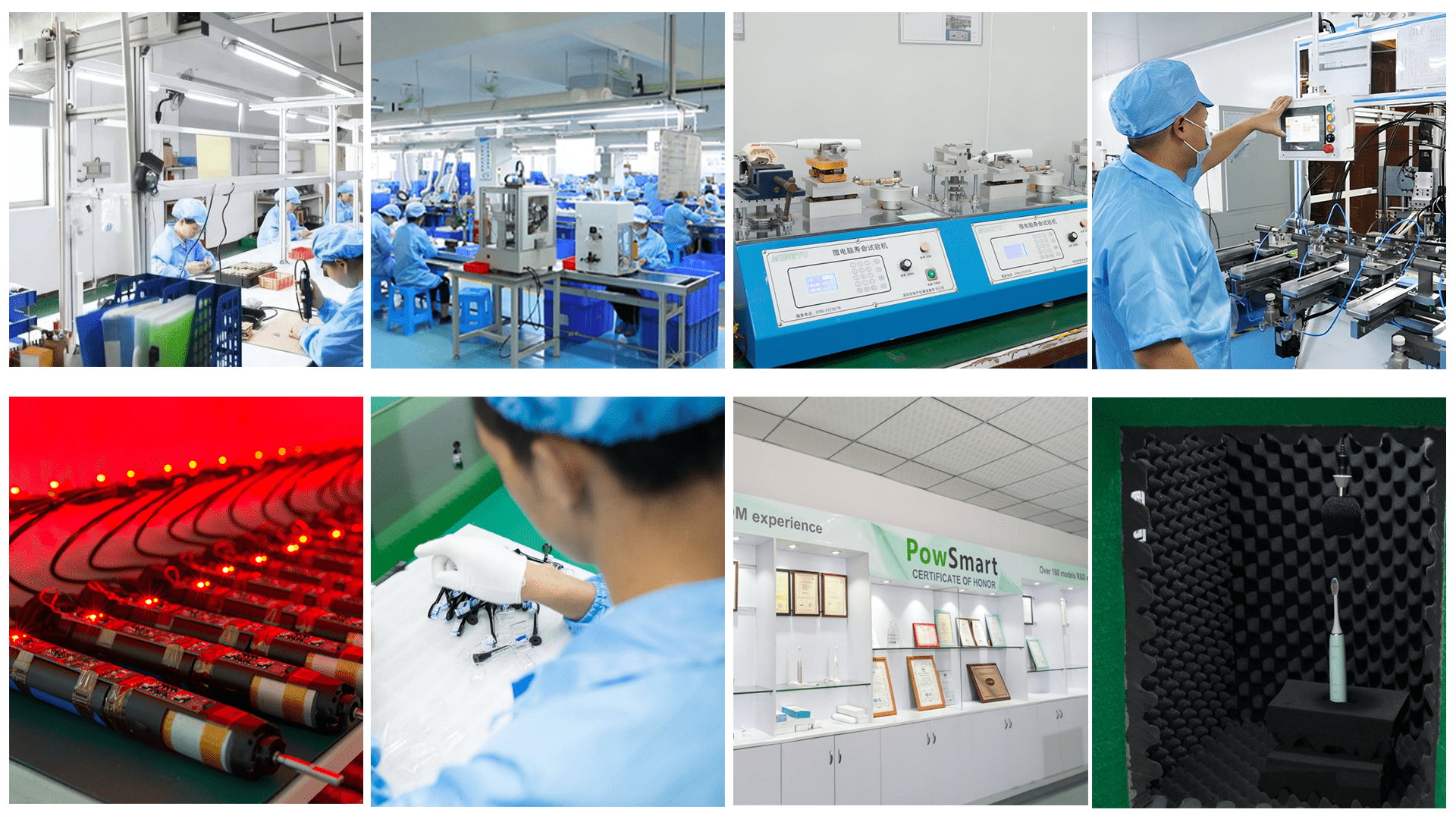

Powsmart adopts energy efficient automated equipment in the production of electric toothbrushes. These equipments not only enhance the production efficiency, but also significantly reduce the consumption of energy. By upgrading the automation of the production line, Powsmart is able to ensure the quality of its products while reducing power consumption and production costs. As a visionary electric toothbrush factory, Powsmart has maximized productivity and reduced energy waste through equipment upgrades, thereby effectively reducing carbon emissions.

Powsmart always adheres to the concept of green production in the manufacturing process. When we manufacture electric toothbrushes, we strictly control the energy consumption in every step of the process to minimize the impact on the environment. The electric toothbrush shell and internal parts are made of environmentally friendly materials and scientifically designed to extend the product’s service life, reducing the waste of resources caused by frequent product replacement.

In daily production, the Powsmart electric toothbrush factory adopts a series of energy-saving measures to effectively reduce energy consumption. The factory has installed an intelligent energy management system to monitor energy consumption in the production process in real-time, to ensure that all equipment is running in the best condition and avoid unnecessary energy waste. At the same time, we regularly maintain and optimize our production lines to maximize the energy efficiency of our equipment.

This energy-saving measure not only reduces the operating costs of the factory but also reduces the consumption of natural resources, helping Powsmart realize a win-win situation for both the environment and the economy.

In the production of electric toothbrushes, Powsmart also attaches importance to waste treatment and recycling. We adopt an advanced waste treatment system to separate and recycle the waste materials generated during the production process, so as to minimize the impact of production waste on the environment. For recyclable materials, the factory makes secondary use of them to reduce the need for new materials.

Through this efficient waste disposal method, Powsmart not only reduces the pressure on the environment from landfills but also saves material costs for the factory and contributes to environmental protection.

After years of efforts, Powsmart has achieved remarkable results in energy saving and emission reduction in the electric toothbrush factory. The factory’s energy consumption and waste emissions have decreased year by year, and the productivity and environmental friendliness of our products have continued to improve. At the same time, our electric toothbrush products have gained wide recognition in the global market. Consumers prefer Powsmart not only because our products are IPX8-rated waterproof and have a low noise level of 55 decibels, but also because of our commitment to sustainable development.

In the future, Powsmart will continue to explore new energy-saving technologies and environmentally friendly production methods to further reduce the carbon footprint of our manufacturing process and continue to provide consumers with high-quality electric toothbrushes through innovative design and the use of environmentally friendly materials. We believe that energy saving and emission reduction in electric toothbrush factories is not only a necessary path for corporate development but also a responsibility to contribute to the earth’s environmental protection.

Powsmart electric toothbrush factory’s achievement in energy saving and emission reduction is due to the company’s unremitting technological innovation and environmental protection concept. Through the use of advanced equipment, the implementation of green production concepts, the implementation of energy-saving measures, as well as waste treatment and recycling, we have effectively realized a double reduction in energy consumption and environmental impact. In the future, Powsmart will continue to promote energy saving and emission reduction and is committed to providing consumers with more environmentally friendly and efficient electric toothbrush products.

What qualifications must a qualified teeth whitening product factory have?

How does a sonic toothbrush work?

Electric Toothbrush Subscription Services: A Guide for OEM Suppliers & Brands

Loose Brush Head Reduces Filament Roundness? Quality Trap Exposed!

Executive Gift Electric Toothbrush Box Set for Diwali

Bulk Kids Electric Toothbrush Supplier Tacoma Schools | Affordable Oral Care

Luxury Gold Plated Electric Toothbrush Wedding Gift Surat

Oral health facts & tips: Teeth whitening

.jpg)

Where to read a Bangalore gadget review for an App-connected toothbrush?

Can Chemical Burns from Whitening Kits Cause Crown Discoloration?

Explaining the Teeth Whitening Device and How to Use It?

The Reasons and Solutions for the Electric Toothbrush Not Responding When Turned On

Electric Toothbrush Christmas Gift Texas

Why Does Poor Cleaning Leave Fiber Residue?

Electric Toothbrush Motor Failure: Common Causes & Solutions

5 Signs Your Electric Toothbrush Is Failing & What It Means for OEM Quality

electric toothbrush heads Charcoal Infuse-Round

electric toothbrush heads Regular Clean

.jpg)

Florida Electric Toothbrush – Powsmart PTR-C8

electric toothbrush heads Ultra Soft

Customization Teeth Whitening Gel

electric toothbrush heads Deep Clean

Electric toothbrush heads Charcoal Infused-Diamond

Private Label Whitening Gel

whstapp

whstapp

National Toll-Free Service Hotline

+86 755 86238638