With the rise of smart oral care devices, battery life has become a top priority for users. However, Brush Head Wear and Battery Degradation often combine to shorten run time—many brushes struggle to last the advertised two‑week charge. In this article, we analyze six key factors behind rapid power loss and recommend practical design improvements and maintenance tips to keep your toothbrush running longer.

Market Expectations and Power Challenges

First, today’s consumers expect a single charge to cover at least two weeks of twice‑daily brushing. At the same time, manufacturers are pressured to deliver smaller, sleeker designs, which limit battery size. Consequently, devices must balance compact form factors with the demands of Brush Head Wear and inevitable Battery Degradation over time—both of which sap run time if left unaddressed.

How Brush Head Wear Increases Motor Load

Next, worn bristles directly drive up energy consumption. As brush heads age:

- Increased Friction: Frayed or splayed bristles no longer glide smoothly, forcing the motor to work harder.

- Higher Current Draw: To maintain vibration amplitude against greater resistance, the drive electronics deliver more current per cycle.

- Heat Build‑Up: Elevated motor load generates extra heat, which accelerates the chemical reactions that cause Battery Degradation.

In short, brush head wear and motor inefficiency form a feedback loop that drains power faster.

The Mechanics of Battery Degradation

Moreover, battery life naturally declines due to:

- Charge Cycle Wear: After hundreds of full discharge/charge cycles, lithium‑ion cells lose active material and capacity.

- Over‑Discharge & Over‑Charge Stress: Without precise cutoff controls, repeated deep discharge or over‑voltage charging damages the cell’s internal structure.

- High‑Temperature Exposure: Storing or operating the brush in hot, humid bathrooms speeds electrolyte breakdown and cell aging.

Together, these factors shrink usable capacity and raise the internal resistance that further shortens run times. Company web:https://www.powsmart.com/product/electric-toothbrush/

The Motor–Battery Feedback Loop

Importantly, brush head wear and battery decay reinforce each other:

- Worn Brush → Higher Load: Increases motor draw and heat output.

- Elevated Heat → Battery Strain: Accelerates Battery Degradation, reducing voltage under load.

- Lower Voltage → Reduced Motor Efficiency: Causes the motor to draw even more current to maintain performance, speeding up both wear processes.

Recognizing this vicious cycle is key to breaking it through targeted improvements.

Design Upgrades and Technical Enhancements

To tackle rapid power loss, manufacturers should consider:

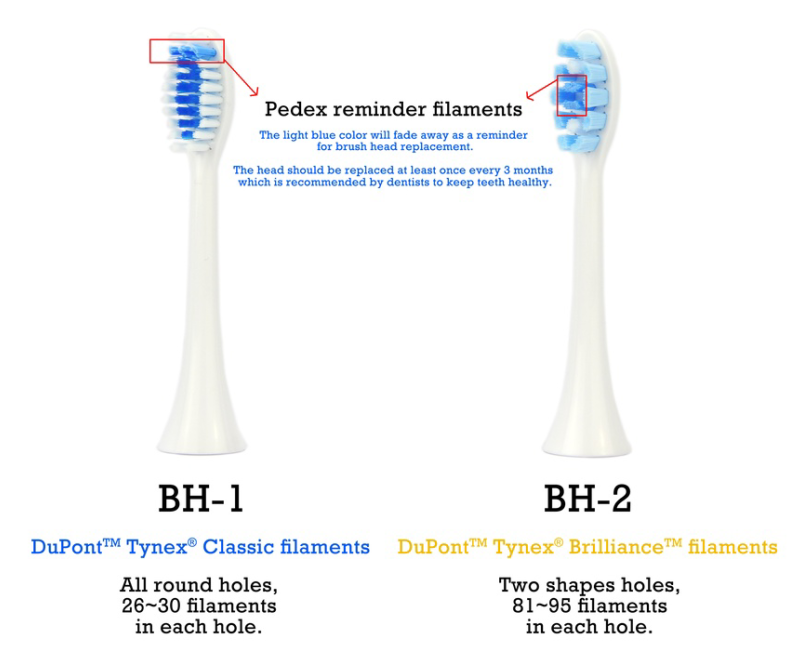

- Durable Brush Materials: Use high‑tensile nylon or advanced polymers that resist fraying and maintain low friction over thousands of cycles.

- Advanced Battery Management: Integrate an MCU‑based charging algorithm with optimized cutoff voltages and over‑discharge protections to minimize cell stress.

- Thermal Regulation: Embed temperature sensors and implement automatic frequency reduction or shutdown when temperatures rise above thresholds.

- Low‑Power Electronics: Select next‑generation microcontrollers and motor drivers with ultra‑low quiescent current and higher drive efficiency.

- Optimized Power Profiles: Tailor vibration amplitude and pulse patterns to clean effectively with minimal energy.

By combining these upgrades, you can significantly extend run time and slow the onset of degradation.

User Maintenance and Best Practices

Finally, prolonging toothbrush life also depends on proper care:

- Replace Brush Heads Regularly: Swap out worn heads every 3 months to prevent excessive motor load.

- Follow Correct Charging Habits: Avoid charging in extreme heat or humidity, and don’t let the battery fully drain before recharging.

- Firmware Updates: Provide over‑the‑air updates that refine power‑saving modes and optimize brushing profiles.

- Proper Technique Training: Educate users on correct brushing pressure and angle to minimize unnecessary mechanical strain.

Combined with smart design, these habits help users maintain peak performance throughout the brush’s lifetime.

Conclusion

When Brush Head Wear and Battery Degradation conspire, even the best brush can run out of power too quickly. However, by implementing durable materials, advanced battery management, thermal safeguards, and guiding users in optimal maintenance, manufacturers can deliver devices that consistently meet the two‑week benchmark—and beyond. For deeper insights into brush head materials, battery technologies, or firmware optimizations, please reach out to our Company!