As oral hygiene products become more advanced, consumers and dental professionals alike are increasingly relying on water flossers (oral irrigators) for deep interdental cleaning. However, one recurring issue is that the water flosser is prone to mold or odor, especially in the water tank after extended use.This blog explores practical and manufacturing-level solutions for preventing mold, with a focus on material choice, structural design improvements, and the integration of technologies such as oral irrigator UVC sterilization.

Understanding the Cause: Why Water Flosser Tanks Develop Mold or Odors

The water tank of a flosser is a moist, enclosed space—ideal conditions for mold growth and bacterial accumulation if not regularly cleaned or dried. Common causes include:

Residual water left in the tank

Poor ventilation in the tank design

Material surfaces that retain moisture

User negligence in maintenance

If left unaddressed, these issues can lead to hygiene concerns and product returns, ultimately damaging brand reputation in the B2B market.

Material Innovation: Anti-Microbial and Easy-Clean Surfaces

One of the first solutions for preventing mold lies in material choice. Manufacturers can reduce the risk of mold and odor by using:

Anti-microbial ABS or PP materials with mold-resistant additives

Food-grade, BPA-free polymers that resist bacterial attachment

Smooth, non-porous finishes that are easy to rinse and dry

Choosing the right material enhances both hygiene and product durability while supporting a cleaner end-user experience.

Structural Design Improvements: Promote Drying and Easy Cleaning

Another key strategy is rethinking the water tank’s internal structure.

Design modifications that can reduce mold risks include:

Removable water tanks for easy rinsing and air-drying

Drainage holes or vent slots to improve airflow

Wide-mouth designs to allow users to manually clean inside

For B2B customers requesting OEM/ODM customization, these enhancements can be promoted as hygiene-focused selling points.

Advanced Tech Integration: Oral Irrigator UVC Sterilization

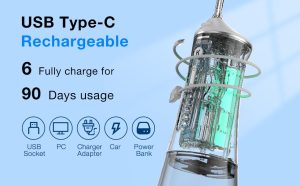

To further elevate hygiene standards, high-end models can incorporate oral irrigator UVC sterilization technology.

Benefits include:

Automatic disinfection of internal water tank surfaces after use

Reduction in microbial load by over 99%

Elimination of odor-causing bacteria without chemicals

This feature is increasingly popular in premium product lines, and offering UVC as part of your OEM/ODM customization adds a competitive edge in the oral care device market.

Maintenance Tips and User Education

While manufacturers can innovate on materials and structure, end-user behavior also plays a critical role. Include clear instructions or visual guides on:

How to empty and dry the water tank after each use

Weekly deep-cleaning practices using mild vinegar or disinfectant

The benefits of regular use of the UVC sterilization function (if included)

By combining product design with user education, you create a full-cycle hygiene solution.

Clean Design for a Cleaner Smile

The fact that the water flosser is prone to mold or odor is a real concern—but it’s also an opportunity for innovation. By implementing:

Smart structural design

Mold-resistant materials

Oral irrigator UVC sterilization

Clear hygiene instructions

Manufacturers can offer a next-generation product that meets both consumer expectations and regulatory hygiene standards.

Looking for expert support in developing or customizing oral irrigators? Our engineering and R&D teams specialize in solutions for preventing mold in water tanks, ensuring your brand delivers quality that lasts.

Contact us to learn how we can help bring cleaner, smarter oral care products to market.https://www.powsmart.com/about-powsmart/