As water flossers become increasingly popular for daily oral hygiene, one question frequently arises from users and distributors alike:

“Why can’t the nozzle of the water flosser be disassembled and replaced like a toothbrush head?” understanding the technical and design reasons behind this decision is essential. In this blog, we dive into the factors that influence nozzle design and explore how water flosser manufacturers prioritize safety, hygiene, and product durability in their engineering choices.

Structural Integration for Safety and Sealing

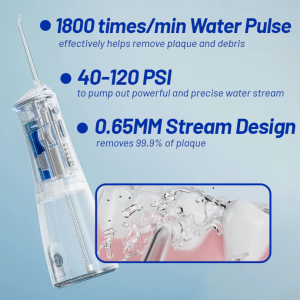

Unlike toothbrush heads, the nozzle of the water flosser is not just an attachment—it is a pressure-sensitive component. Many nozzles are structurally integrated with the body or water channel to ensure:

- Leak-proof performance under high-pressure water pulses

- Consistent water flow rate and pressure balance

- Protection against backflow contamination

Allowing users to disassembled and replace the water flosser nozzle without proper sealing mechanisms could result in water leakage, reduced device efficiency, or even user injury.

Hygiene and Sterilization Considerations

From a medical and hygiene standpoint, a fixed or semi-fixed nozzle design allows manufacturers to:

- Use biocompatible, sterilization-friendly materials

- Ensure internal cleanliness by reducing user tampering

- Prevent bacteria buildup inside the joint between the nozzle and the body

Leading water flosser manufacturers conduct extensive testing to ensure the internal structure remains sterile and safe throughout regular use. A detachable nozzle may introduce hygiene risks that are difficult to control in non-clinical settings.

Engineering for Long-Term Durability

A fixed nozzle design offers superior durability over time. Repeated insertion and removal of a detachable nozzle can cause:

- Wear and tear on locking components

- Loosening of the water channel or seals

- Increased failure rate over product lifetime

For this reason, many manufacturers prefer to design the nozzle of the water flosser as a semi-permanent part, engineered to last through the device’s full usage cycle.

Customized Designs and OEM Requests

That said, some professional water flosser manufacturers do offer OEM/ODM options where replaceable nozzles are available—especially for products intended for multi-user or clinical use.

In such cases, manufacturers implement:

- Secure locking mechanisms

- User-friendly nozzle ejection systems

- Optional nozzle sets with color coding for different users

This allows brands to strike a balance between convenience and safety based on their target audience.

Conclusion: Design Decisions for Function and Safety

The decision not to allow users to freely disassemble and replace the water flosser nozzle is not a limitation—it’s a deliberate design choice:

Maximizing pressure performance

Ensuring hygienic operation

Extending product durability

At the same time, advanced water flosser manufacturers provide customized solutions for brands needing replaceable nozzles, ensuring both flexibility and safety.

📩 Looking to develop a custom water flosser with replaceable nozzles? Contact our engineering team for tailored OEM support.https://www.powsmart.com/contact-us/