In today’s highly competitive global market, businesses must prioritize both Manufacturing Standardization and Branding to establish a strong presence and ensure product consistency. Standardized manufacturing processes not only guarantee high-quality production but also build consumer confidence, while strategic branding enhances recognition and market positioning. By integrating these two essential elements, companies can achieve sustainable growth and global trust.

Why Manufacturing Standardization Matters

Consistency in manufacturing is the foundation of product reliability. Without strict Manufacturing Standardization, variations in quality, performance, and safety can arise, leading to customer dissatisfaction and brand reputation risks.

Standardization ensures:

- Uniform product quality – Every unit meets the same high standards, reducing defects and recalls.

- Regulatory compliance – Products meet international safety and industry certifications (CE, ISO, FDA, etc.).

- Production efficiency – Streamlined operations reduce waste, optimize resources, and lower costs.

- Scalability – A structured manufacturing process supports rapid expansion without compromising quality.

With an optimized production system in place, businesses can maintain consistency while improving cost efficiency, ultimately gaining a competitive edge in the market.

Key Elements of Standardized Manufacturing

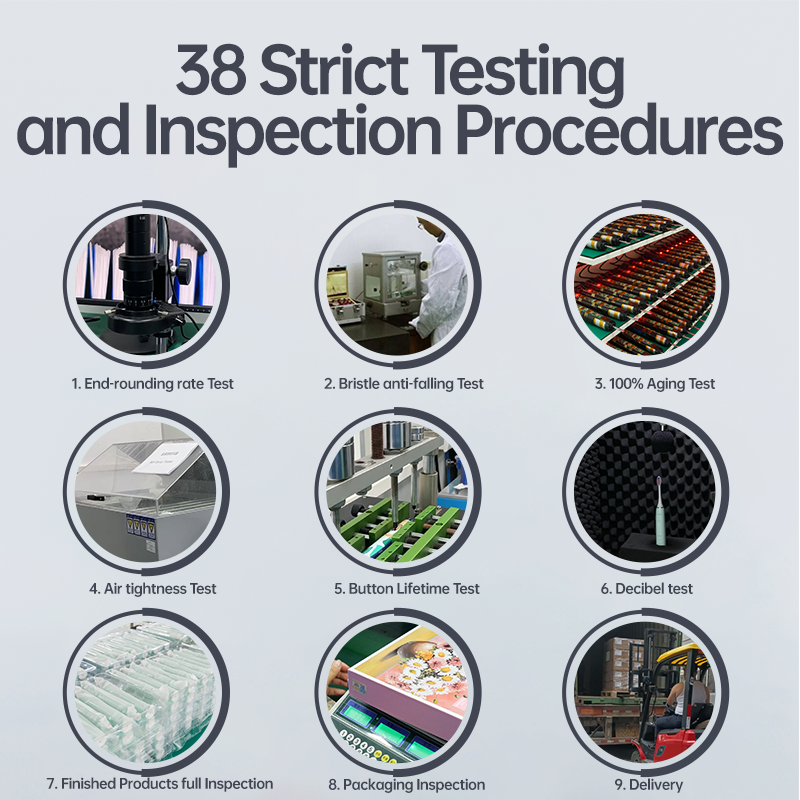

Achieving high-quality Manufacturing Standardization requires a structured approach. Our factory implements:

- Automated Production Lines – Reducing human errors and improving efficiency through precision robotics.

- Strict Quality Control (QC) Systems – Implementing multi-stage inspections, from raw materials to finished goods.

- Real-Time Monitoring & Data Analytics – Utilizing AI-driven tracking for process optimization and predictive maintenance.

- Compliance with Global Standards – Meeting CE, ISO 9001, and other required certifications for safe and reliable products.

By adopting these practices, we ensure every product meets the same level of excellence, reducing inconsistencies and enhancing customer trust.

The Power of Branding in Manufacturing

While standardization guarantees quality, Branding is what differentiates a company in the marketplace. A strong brand identity fosters customer loyalty, improves market reach, and increases perceived value.

Key branding strategies include:

- Custom OEM/ODM Solutions – Tailoring product designs, colors, and packaging to align with brand aesthetics.

- Private Labeling – Allowing businesses to create exclusive product lines that strengthen brand recognition.

- Storytelling & Brand Positioning – Communicating the brand’s mission, values, and commitment to quality.

- Marketing & Customer Engagement – Leveraging social media, influencer partnerships, and digital campaigns to build trust.

By integrating Branding into the manufacturing process, businesses can create unique, high-quality products that resonate with their target audience.

The Role of Certification in Building Brand Credibility

Certification plays a crucial role in bridging Manufacturing Standardization and Branding. Recognized certifications not only verify product safety but also enhance brand credibility, making it easier to enter international markets.

Our manufacturing processes comply with:

- CE Certification – Ensuring compliance with European Union safety standards.

- ISO 9001:2015 – Guaranteeing a structured quality management system.

- FDA Approval – Meeting health and safety regulations for medical-grade products.

Ultimately, by obtaining and maintaining these certifications, we help brands establish trust with global consumers while ensuring seamless market entry.

Scaling Business Growth with Standardized Production & Branding

A well-executed combination of Manufacturing Standardization and Branding enables businesses to scale efficiently while maintaining product integrity. Our partners benefit from:

- Faster time-to-market – A structured process accelerates production and distribution timelines.

- Cost-effective production – Reduced waste and optimized supply chain management lower operational costs.

- Stronger brand recognition – High-quality, consistently branded products enhance customer loyalty and competitive positioning.

- Flexible production capabilities – Adaptability to meet market demands without sacrificing quality or brand consistency.

By establishing a strong foundation in both manufacturing and branding, businesses can expand their market reach while delivering reliable products to consumers worldwide.

Partner with Us for Standardized Manufacturing & Brand Growth

As an industry leader in Manufacturing Standardization and Branding, we offer full-service OEM/ODM solutions, ensuring that every product meets high-quality benchmarks while supporting brand differentiation. Whether you’re launching a new product line or optimizing an existing one, our expertise guarantees seamless production and strategic branding support.

Contact us today to explore how we can help you achieve consistent quality and global trust.

-300x169.jpg)