If you’re looking to expand your product offerings, understanding the OEM process of water flossers is crucial. In this blog, Powsmart will explore the detailed production process of water flossers, highlight the role of an OEM water flosser supplier, and discuss how partnering with a reliable oral irrigator manufacturer can drive business success.

Understanding the OEM Process of Water Flossers

The OEM process of water flossers involves a partnership between a brand and a manufacturer to produce custom-labeled oral irrigators. This process includes:

- Conceptualization: Brands collaborate with the manufacturer to define specifications, such as design, features, and target market preferences.

- Prototyping: The oral irrigator manufacturer creates prototypes based on the agreed specifications, allowing for adjustments before mass production.

- Material Selection: Selecting High-quality materials is to ensure durability, safety, and functionality.

The Production Process of Water Flossers

The production process of water flossers typically includes the following steps:

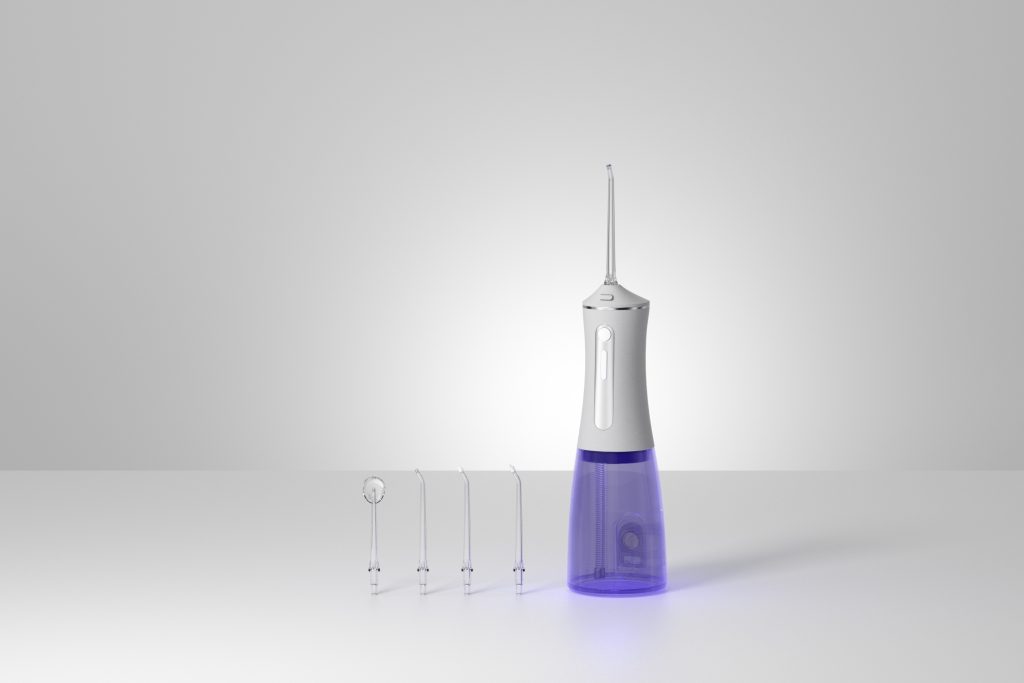

- Component Manufacturing: Key parts like water tanks, nozzles, and motors produced with precision to meet performance standards.

- Assembly: Components are assembled in a controlled environment to ensure quality and functionality.

- Testing: Rigorous testing is conducted to check for water pressure consistency, durability, and safety compliance.

- Branding and Packaging: The final products are customized with the client’s branding and packaged according to their requirements.

Partnering with an experienced OEM water flosser supplier who streamlined their production process could help brand expand their market share efficiently.

The Role of Oral Irrigator Manufacturers

A reliable oral irrigator manufacturer plays a pivotal role in the success of an OEM project. Normally reliable manufacturers feature with:

- Offer Expertise: They bring years of experience in designing and producing high-quality water flossers.

- Ensure Compliance: They adhere to global safety and quality standards, ensuring the product meets market regulations.

- Support Customization: From color schemes to advanced features like UV sterilization, manufacturers enable brands to create unique products.

Working with a trusted manufacturer ensures the OEM water flosser project runs smoothly and delivers products that align with consumer expectations.

Benefits of OEM Water Flossers for Businesses

For brands entering the oral care market, the OEM process of water flossers offers several advantages:

- Cost Efficiency: Partnering with an oral irrigator manufacturer eliminates the need for in-house production facilities.

- Market Adaptability: Customized designs and features allow brands to target specific consumer demographics.

- Quick Time-to-Market: With the manufacturer handling production, brands can focus on marketing and sales strategies.

Conclusion

The OEM process of water flossers is a comprehensive approach that allows brands to deliver high-quality products without direct manufacturing. By understanding the production process of water flossers and collaborating with a trusted oral irrigator manufacturer, businesses can ensure product excellence and market competitiveness. For companies aiming to enter or expand in the oral care industry, OEM partnerships provide a strategic path to success. Powsmart has been providing OEM/ODM service for over 20 years, Contact us if you have any questions regarding to the OEM process of water flossers.