Electric toothbrushes have become a staple in oral hygiene routines worldwide. However, ensuring durability and minimizing the failure rate of electric toothbrush devices is critical for brand reputation and customer satisfaction.

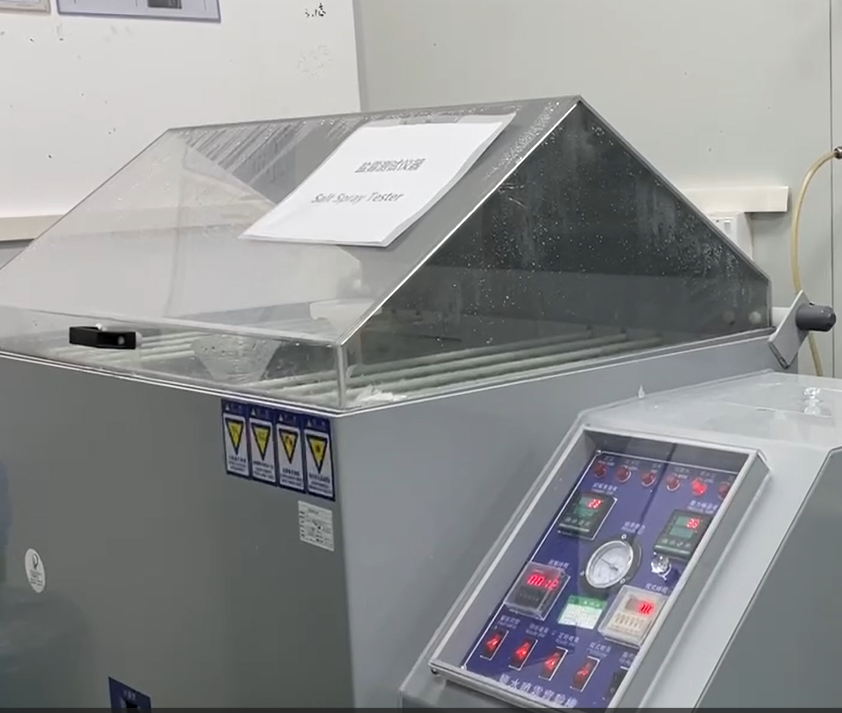

The foundation of a reliable electric toothbrush starts with thoughtful design. Using high-quality materials and components, such as water-resistant seals and durable motors, can significantly reduce mechanical and electronic failures. Additionally, ergonomic designs that withstand daily use and accidental drops are vital. Many electric toothbrush factories now incorporate advanced testing during the design phase to ensure their products meet these durability standards. As for this, Powsmart’s electric toothbrush models are all using patented designed motors. Based on Powsmart’s previous manufacturing experience, We also have our own patented water resistance technology.

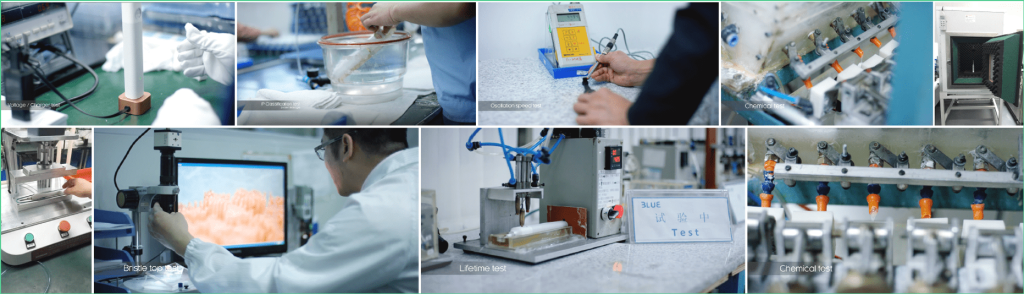

A robust quality control process is essential for maintaining electric toothbrush quality. Factories should implement multi-stage inspections, from raw material checks to final assembly testing. Common issues like battery malfunctions and bristle wear can often be detected and addressed during production.

As modern electric toothbrush factory, Powsmart is also using automated systems to ensure consistent quality. For example, real-time monitoring of assembly lines can quickly identify defects, minimizing the risk of faulty products reaching consumers.

Many electric toothbrush failures stem from improper use or lack of maintenance. Providing clear instructions and usage tips to customers can prevent common problems such as water damage or overcharging. Including information on how to properly clean and store the toothbrush can also extend its lifespan.

For instance, brands that share care tips, such as “Avoid leaving the toothbrush in a damp environment,” report fewer complaints about premature malfunctions.

The reliability of your toothbrush components depends largely on your suppliers. Establishing strong relationships with trusted suppliers ensures access to high-quality materials. Batteries, motors, and waterproof components from reputable sources are less likely to contribute to the failure rate of electric toothbrush devices. Working closely with suppliers to standardize materials can further enhance the overall product quality. Contact Powsmart if you want to customize your own branded electric toothbrush. https://www.powsmart.com/contact-us/

.jpg)

Seeking a Toothbrush Industry Partner for Toothbrush Market Expansion?

.jpg)

The Secret of the Cross-Sectional Shape of Electric Toothbrush Bristles: The Difference Between Diamond, Round and Cone in Protecting Gums

Highly Effective Electric Toothbrush Changes Your Oral Care Habits

Swivel Blockage Leading to Saliva Depletion – Preventable?

.jpg)

Dallas Electric Toothbrush Private Label Services Including Custom Packaging

Holi Family Gift Pack Electric Toothbrush Ahmedabad

Post-Surgery Risks Worsened by Jaw Discomfort?

Tampa Charger Replacement: Reliable Factory-Supplied Power Solutions

Can Teeth Whitening Kits Trigger Oral Ulcers?

Groom Grooming Gift: Men’s Electric Toothbrush OEM Manufacturing

How Waterproof Technology Patents Enhance the Competitiveness of water flossers?

Grip Fatigue with Noise Pollution – Design Flaw?

Why a College essential toothbrush tops Student oral care lists

Difference between sonic toothbrush and sweeping electric toothbrush

Wireless vs. Contact Charging: Which Is Better for Electric Toothbrushes?

ISO 13485 Certification Interpretation: How Do Electric Toothbrush Meet Medical Device-Grade Production Standards?

electric toothbrush heads Charcoal Infuse-Round

electric toothbrush heads Deep Clean

.jpg)

Florida Electric Toothbrush – Powsmart PTR-C8

Customization Teeth Whitening Gel

electric toothbrush heads Ultra Soft

electric toothbrush heads Regular Clean

Private Label Whitening Gel

Electric toothbrush heads Charcoal Infused-Diamond

whstapp

whstapp

National Toll-Free Service Hotline

+86 755 86238638