In the electric toothbrush market, the electric toothbrush cost difference vary significantly from different factories, and there are many complex factors behind this. Understanding the difference in the cost of electric toothbrushes and the factors that affect them can help brands make more informed decisions when choosing suppliers.

The raw material cost of electric toothbrushes is an important factor affecting the overall production cost. The price of high-quality batteries, motors, plastic casings and other materials will directly affect the cost of electric toothbrushes.

Common battery types are: alkaline batteries, nickel metal hydride batteries (NiMH) and lithium-ion batteries. Alkaline batteries Alkaline batteries are non-rechargeable batteries, but they have extremely low self-discharge rates and costs. NiMH batteries or lithium-ion batteries are rechargeable batteries. NiMH batteries cost less than lithium-ion batteries. Electric toothbrushes using lithium-ion batteries usually have higher raw material costs than products using nickel metal hydride batteries.

Not only that, the design of portable devices like electric toothbrushes depends largely on the performance of the battery. The key indicator of the battery is of course the battery life. A good electric toothbrush does not need to replace the battery frequently, nor does it need to charge the battery frequently, so that the battery “disappears” from the user’s eyes. All Powsmart electric toothbrush models use 18650 lithium batteries, which have excellent battery performance and battery life, and can be used for at least 90-250 days. In addition, the capacity of the lithium battery is also one of the reasons for the cost difference. https://www.powsmart.com/about-powsmart/

The motor is one of the biggest factors affecting the cost difference of electric toothbrushes. At present, there are two types of motors for sonic electric toothbrushes: eccentric motors and magnetic levitation motors. The magnetic levitation motor is more expensive than the eccentric motor, and the performance is also better. For example, it has stronger power, weaker vibration, and is silent. It is in a left-right swing mode. The process of moving along the gum line can sweep the entire tooth surface, while the eccentric motor is in an up-down, left-right vibration mode, which is easy to hit the gums during use. In addition, the splash caused by the magnetic levitation motor after entering the water is larger, which is conducive to driving the water flow to flush the gaps between teeth when brushing teeth.

According to market research, raw material costs can account for 40%-50% of the cost of electric toothbrushes.

The production process used by different factories can also lead to differences in the cost of electric toothbrushes. Advanced production lines and automated equipment can improve production efficiency and product consistency, reduce labor costs and scrap rates. For example, some high-end electric toothbrush manufacturers have reduced labor costs by introducing robotics technology, reducing product costs by 15%-20%. In contrast, factories using traditional production processes have low production efficiency and naturally increase costs.

Technical R&D and innovation investment in electric toothbrushes is another cost factor. High investment in R&D can bring more competitive products to meet the diverse needs of the market. Typically, leading electric toothbrush manufacturers invest 5%-10% of their total revenue in R&D each year, and this part of the cost will be reflected in the final product price. Therefore, factories with less R&D investment usually have lower electric toothbrush costs, but may be at a disadvantage in market competition.

The production scale of the factory will also significantly affect the cost of electric toothbrushes. Large-scale production can dilute fixed costs, thereby reducing the cost per unit product. For example, a factory with an annual output of more than 500,000 electric toothbrushes has a cost per product that is about 20% lower than a factory with an annual output of 100,000. Therefore, larger factories have more advantages in market competition.

Labor costs vary from region to region and directly affect the production cost of electric toothbrushes. Generally speaking, regions with lower labor costs can reduce overall production costs, making product prices more competitive. According to statistics from the International Labor Organization, labor costs in Southeast Asia are only 30%-40% of those in Europe and the United States, which has led many electric toothbrush manufacturers to choose to set up factories in Southeast Asia.

Although strict quality control processes will increase production costs, they can effectively reduce the risks of after-sales service and returns. High-quality electric toothbrushes usually require higher quality standards and testing processes, which will be reflected in the cost. Companies that implement strict quality control often have customer satisfaction rates as high as 90%, so although short-term costs increase, in the long run, brand loyalty and market share can be improved. Powsmart was once one of Apple’s authorized manufacturers. It continues the strict quality control procedures in the product production process and implements 38 quality inspections for each electric toothbrush shipped out of the factory.

The difference in the cost of electric toothbrushes comes from multiple factors, including raw material costs, production processes, R&D investment, production scale, labor costs and quality control. Understanding these factors can help brand owners make more rational decisions when choosing electric toothbrush manufacturers, while seeking the best cost-effectiveness in a highly competitive market. Through reasonable cost control and effective resource allocation, electric toothbrush manufacturers can maintain market competitiveness while improving product quality. If you want to know more about the specific information of electric toothbrush customization service, contact us!

.jpg)

Need a Toothbrush Business Providing Toothbrush Samples?

Can Teeth Whitening Gel Be Used Alone to Whiten Teeth?

Electric Toothbrush with Tongue Cleaner Wholesale | Bulk OEM for Oral Hygiene Enhancements

OEM Considerations for Battery Technology in Electric Toothbrushes

Seeking a Toothbrush Sustainable Supplier?

.jpg)

Can a Florida electric toothbrush soothe Florida sensitive gums?

Understanding MOQ Variations for Custom Electric Toothbrush Colors

Silent Electric Toothbrush for Hotels

Are Water Flossers Bad for You? Safety Evaluation

Best Electric Toothbrush for Outdoor Enthusiasts – Durable & Waterproof OEM Options

.jpg)

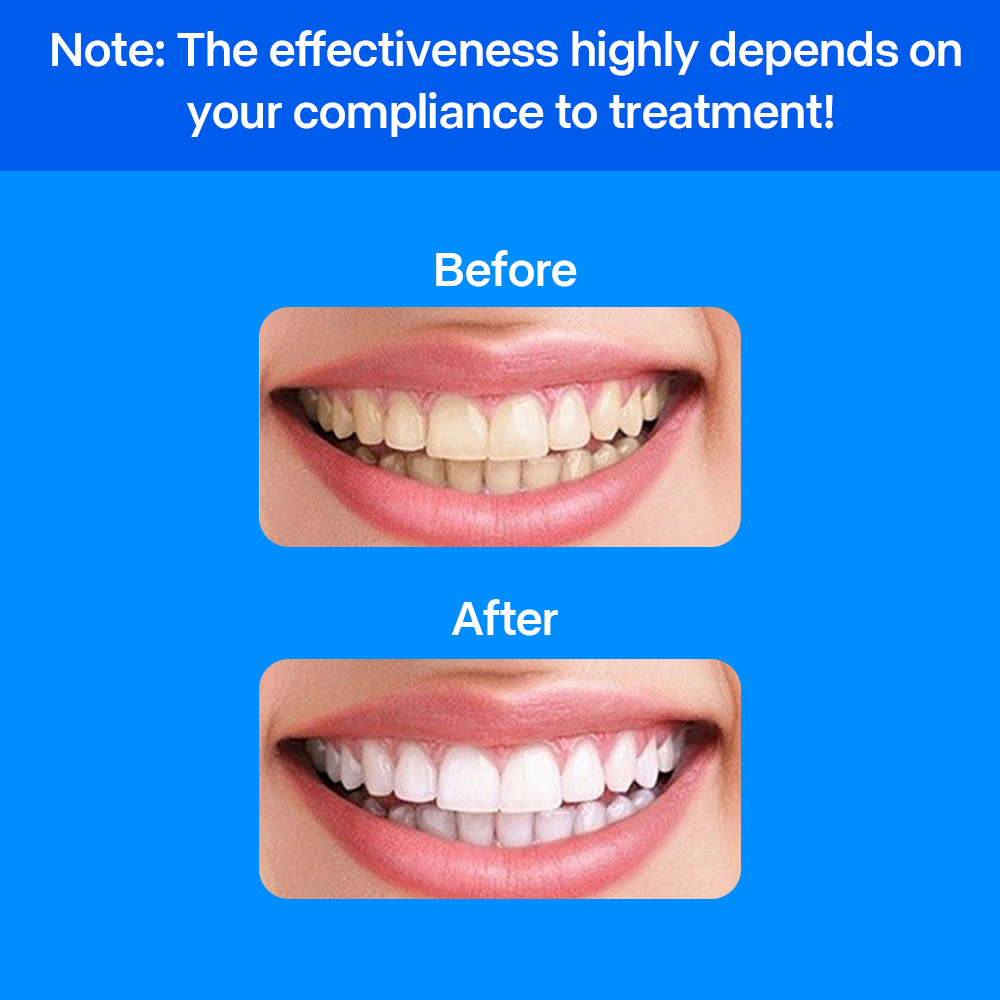

Does Teeth whitening gel guarantee Professional results?

Gingival Abrasion with Saliva Depletion – A Silent Crisis in Oral Care Design?

How to Choose the Type of Charging Method for Electric Toothbrushes?

.jpg)

Can Innovative Water Flosser Design Incorporate an Ergonomic Flosser Handle for User Comfort?

Wireless Charging Toothbrush | OEM Manufacturer for Premium Oral-Care Brands

The Top Things You Need to Know About Teeth Whitening

electric toothbrush heads Regular Clean

electric toothbrush heads Ultra Soft

electric toothbrush heads Charcoal Infuse-Round

Private Label Whitening Gel

Customization Teeth Whitening Gel

Electric toothbrush heads Charcoal Infused-Diamond

.jpg)

Florida Electric Toothbrush – Powsmart PTR-C8

electric toothbrush heads Deep Clean

whstapp

whstapp

National Toll-Free Service Hotline

+86 755 86238638